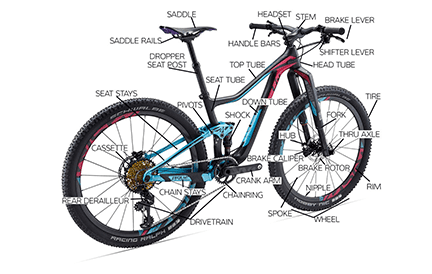

To begin, we’ll go through the most basic components of most bike hubs as well as how they function. In general, front hubs are relatively simple. Mtb hubs body/ shell are the primary components. This component connects the brake rotor to the spokes (if applicable). On often confuses “shell” with “body.” Front hubs typically have two bearings, one on each side. In modern hubs, sealed cartridges bearing are probably the more popular type. The portions of the hub that connect with the fork drop-outs to place the tyre in the fork are known as end caps. These are frequently replaceable in order to convert a hub to various axle standards. A bearing sleeve or axle is a sleeve that runs between the two hub bearings and interacts with the fork axle. And it is generally affixed to the end caps.

- Part 1: Introduction to Mtb Hubs

- Part 2: Why Should You Pay More on Hubs

- Part 3: What is the Function of a Hub

- Part 4: What is the best MTB Hub for You

- Part 5: What Features Should You Look for in a Mountain Bike Hub

- Part 6: The Best Mountain Bikes Hubs in the Market

- Part 7: Conclusion

Part 1: Introduction to Mtb Hubs

Best mtb hubs for your new mountain bike wheels. Are you a bee or a ghost? Depending on your mountain bike hubs, you will either be able to cuddle close to your ride mates or be heard from a mile away. Less important than freehub noise, hubs determine how far you can turn the pedals before your rear wheel begins spinning and how frequently you must regrease your bearing. The front and rear hubs are clearly distinct. Regardless of the manufacturer, front hubs are a rod with an axle, bearings, and a disc brake attachment. While rear hubs also contain ratchet and free characteristics, the design and execution vary widely across brands. However, check out Bike Perfect’s top picks for the best mtb hubs if you’re building a new set of custom wheels.

Part 2: Why Should You Pay More on Hubs

The following is true of higher-end bike hubs mtb in general (with a few outliers, which I’ll discuss later):

- They’re not as heavy.

- They’re more long-lasting and durable.

- They are more serviceable and have more readily available replacement parts.

- They provide greater opportunities for interaction.

- They include better smoother running bearings and superior sealing from the environment.

- They’re available in a variety of gleaming anodized hues.

Part 3: What is the Function of a Hub

The mtb hub. That’s all it does. It is possible to gather data from many ports. It lacks routing functionality and other complex networking functions. They are called pawls because they bite into the wheel ratcheting while pedalling forward. When coasting or pedalling backwards, the pawls disengage. The stronger springs and more pawls and engagement points in higher-end hubs produce louder and more powerful noises. Modern hubs also utilize lesser oil, allowing the springs to move more easily. The stronger springs and more pawls and engagement points in higher-end hubs produce louder and more powerful noises.

Bearing type

The key to a long and healthy hub is good-quality bearings that are sealed as well as protected by dirt and water. Cup & cone bearings, which have two rings of free bearing that sit in ‘cups’ inside the hub body and are held in place by conical nuts classified as ‘cones,’ are used in older or even less expensive hubs. Moreover, each unit, which makes up one bearing, allows the balls to freely revolve between the cups and cone.

Part 4: What is the best MTB Hub for You

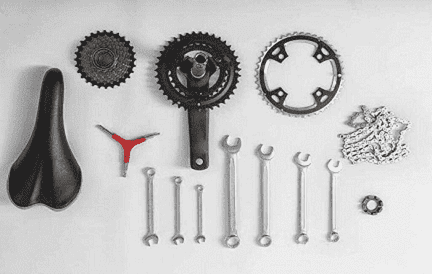

Aside from the obvious question of front vs. rear, there are several factors to consider when purchasing a new mtb hub or hub set, including bearing type materials, disc mount standard axle type, and rims. Cup and cone hinges have always had the advantage of being simple to maintain at home – all you need are new bearings and a dab of grease every now and then to keep them operating smoothly but they can be difficult to adjust correctly. Cartridge bearings, which rotate steel balls and needles in a single cartridge component that can be readily removed for repair or replaced if worn out, are used in more expensive hubs. Many riders prefer cartridge bearings because they eliminate the need for painstaking micro-adjustment or searching for stray bearings in the middle of a ride but they are more costly to replace.

Materials

Most front and rear MTB hubs will be built of lightweight aluminium alloy, however, carbon fibre components will be available at the high end of the market. Steel rather than aluminium freewheels may be used in rear hubs for trail jump, and gravity bikes to avoid the softer alloy curves from being eaten away by the cassette under severe load.

Brake Rotor Suitability

Disc brake bikes require hubs that the disk rotor can mount to. Six-bolt and Centre lock are the two basic rotor mounting standards. Six bolt systems have hubs with six evenly spaced holes for bolting on a matching rotor, as the name implies. Because rotor bolts typically feature Torx heads, you’ll need a Torx tool to tighten or loosen them. Don’t try to wing it with an Allen key as you’ll risk ripping the bolts.

Shimano’s Centre lock technology replaces rotor bolts with a splined hub-rotor contact secured by a locking ring special tool needed. Although this is said to save time during installation, it does restrict the mixing and matching of hubs and brakes, as most other manufacturers use the six-bolt system. Adaptors for mounting six-bolt rotors to Centre lock hubs and vice versa are available. Check which disc interfaces you’re currently using before buying in new hubs and buy accordingly.

Part 5: What Features Should You Look for in a Mountain Bike Hub

Bearings

Cup & cone angular contacting bearings or sealed cartridges bearings are available, depending on the model of the hub you choose. Loose ball bearings are inserted in a cup within the hub as well as forced in with a con the balls freely rotate between each structure as the wheel revolves. A pre-schooler can service a cup & cone-bearing with just a glob of fresh oil, but fine-tuning the bearing pressure requires a little more effort. The hub will have a play if the bearing tension is too loose which might harm the internals. If the bolt is too tight, the bearing will not spin freely, causing excessive wear on the hardware in cup and cone bearings.

Cartridge bearings, on the other hand, have everything bundled into a sealed unit making them considerably quicker to replace and requiring no tension adjustment. However, they are a little more complex to service. To open one, carefully peel off the waterproof seal remove the old oil, degreaser, and load them with fresh lubricant before restoring the seal being cautious not to fold and damage it. The cost of replacing sealed bearings is considerably higher.

Material

The majority of MTB hubs are built of alloy, with carbon fibre being used in select ultra-high-end models to save weight. Steel hubs intended for gravity riding are used if the weight cost is justified by the risk of catastrophic failure.

Mounting for the Rotor

For disc rotors, hubs will feature either a six-bolt or a centre-lock mount. The rotor and mounting components counteract any weight reductions or gains on the hub.

Axle Spacing and Axle

What is the axle size of your fork? Is it 12mm, 15mm, or 20mm in diameter? Perhaps a 5mm quick release? But the industry appears to have stabilized at 15mm with most mountains bikes with downhill bikes moving up to 20mm.

Then there’s the spacing; you have non-boost, boost, and, in rare situations, super-boost options. Non-boost hubs are 100mm broad in the front & 135 and 142mm wide in the back, whereas boost hubs are typically 110mm wide in the front & 148mm wide in the back. This not only makes the wheel stiffer by increasing the gap between the flanges, but it also pulls the chain line out 3mm, allowing for fatter tyres. For years, super boost space has been standard on DH bikes, but a few brands, such as Pivot, are now spacing bikes with 157mm back hub space to provide a broader brace angle for spokes as well as stronger wheels. Many hubs now include removable end caps to help with sizing and spacing issues.

Freehub

You will also need to consider the type of freehub body you will need based on your drive train and cassette. SRAM has switched to one-piece cassettes because of its 11 or 12-speed drive trains in recent years, which necessitates the use of an XD driver. With Shimano’s new 12-speed drivetrain comes a revolutionary Micro-Spine freehub, which created some controversy at launch since Shimano took its time releasing the specs to firms like Hope. You’ll need a normal HG style freehub frame if you’re still using a Shimano ten or eleven-speed drivetrain.

Part 6: The Best Mountain Bikes Hubs in the Market

Industry Nine Hydra

SPECIFICATIONS:

- There are so many opportunities for interaction.

- Six-bolt and centre lock brake mount

- 690 points of interaction

- Cartridge kind of bearing

- REASONS TO BUY: +690 engagement points +Anodized hub shell

- REASONS TO STAY AWAY -The cost

They have 690 points of contact with 0.52 degrees between them, making them almost instantaneous.

DT Swiss DT350

SPECIFICATIONS:

- Hubs that will survive your wheels and won’t break the bank

- Brake mounting options include six-bolt and centre mounts.

- Engagement points: 18

- Cartridge kind of bearing

- REASONS TO BUY= Price +Serviceability

- REASONS TO AVOID -Weight -Some too technical features that necessitate ratcheting.

Despite being slightly heavier than the more costly DT 240 hubs, the DT-Swiss 350 hubs deliver substantial performance and dependability for the money. They come in a variety of axle & spacing configurations, and because the Star-Ratchet works so well, many bike manufacturers have licensed the DT technology to use in their own hubs.

Hope Pro 4

SPECIFICATIONS:

- Is ideal for muddy terrain in the UK.

- Six-bolt brake mounts

- Points of contact: 44

- Cartridge kind of bearing

- REASONS TO BUY: Precision built with high standards +Easy maintenance +A wide range of options

- REASONS TO AVOID -There isn’t a centre lock.

It’s no surprise that Hope’s Pro-4 Hubs operate well in classic British conditions. They’re highly sealed, so much so that re-sealing the rear hub needs some strain.

ISO Chris King

SPECIFICATIONS:

- The gold standard for buzzy bees

- Six-bolt brake mounts

- Points of contact: 72

- Cup and cone bearings are the two types of bearings available.

- The sound of frictionless bearings is one of the best reasons to buy.

- AVOID FOR THESE REASONS: -Price

Chris King’s buzzing bee, hubs, is the gold standard. With fewer points of contact, the Drives Ring freehub system nevertheless boasts the highest serviceability, reliability, and buttery-smooth bearings.

Part 7: Conclusion

Above is the whole discussion all about mtb hub components and their functions. Hope it’ll assist you to choose the best mountain bike hubs.